Overview

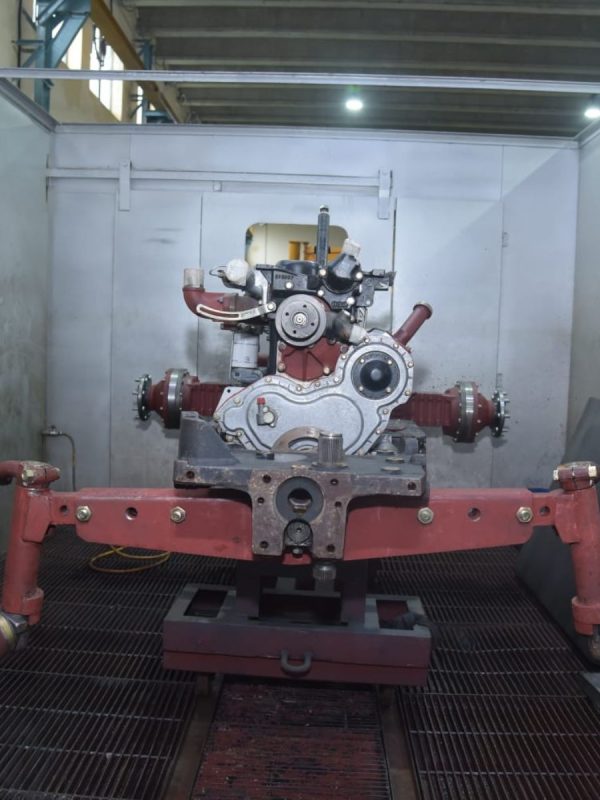

The roller test is a crucial stage in the manufacturing process of machinery, particularly vehicles, where prototypes undergo dynamic testing to evaluate operational efficiency and performance. This test involves subjecting the vehicle to simulated road conditions on a rolling road or dynamometer, allowing engineers to measure parameters such as engine power, acceleration, braking, and fuel consumption.

Advantages

Performance Validation

Roller test validates performance of vehicles under simulated driving conditions, ensuring they meet or exceed specified performance metrics for power.

Efficiency Optimization

By replicating real-world driving scenarios in a controlled environment, manufacturers can identify any issues or inefficiencies and fine-tune the vehicle’s design to optimize performance. The roller test serves as a vital quality assurance measure, ensuring that vehicles meet stringent standards for safety, reliability, and customer satisfaction.

While road testing evaluates vehicles in real-world conditions, the roller test provides a controlled environment for assessing performance and efficiency under standardized conditions.

A wide range of vehicles, including cars, trucks, buses, and agricultural machinery, may undergo roller testing to assess performance, efficiency, and compliance with regulatory standards.

The duration of a roller test varies depending on factors such as the complexity of the vehicle, the scope of testing required, and the specific parameters being evaluated. It can range from a few minutes to several hours.

Email

info@ptmc.com.pk

Location:

16 km Multan Road, Pakka Mile Stop Shahpur, Lahore, Pakistan