Overview

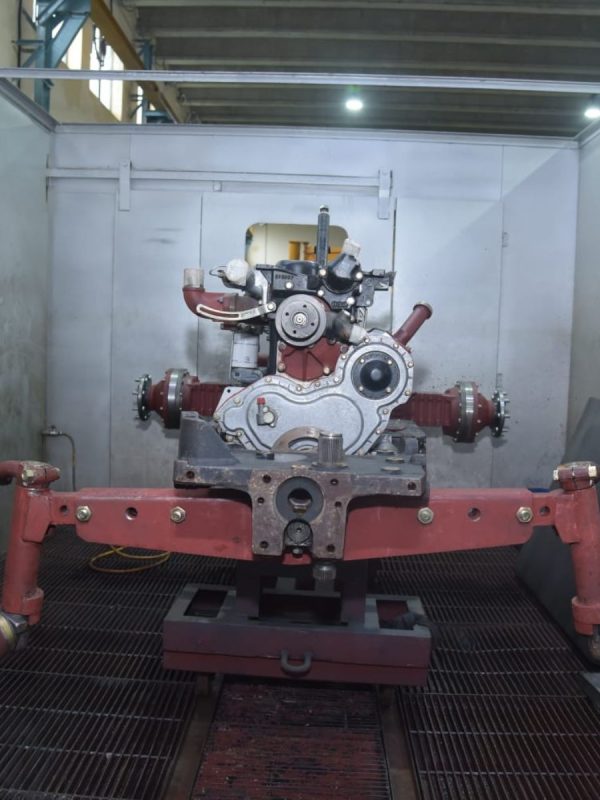

The Quality Assurance (QA) laboratory is the nucleus of precision and excellence in manufacturing, where meticulous testing and analysis validate the integrity and performance of products. Equipped with state-of-the-art equipment and staffed by skilled technicians, the QA laboratory conducts a battery of tests to assess factors such as durability, reliability, and adherence to specifications.

Advantages

Consistent Quality

Ensures consistent quality across production batches, minimizing variability, standards & specifications.

Compliance Assurance

By adhering to rigorous quality control measures & regulatory requirements, manufacturers provide assurance.

From material composition analysis to stress testing and quality control checks, every aspect of product quality is scrutinized to uphold the highest standards. Through rigorous QA procedures, manufacturers safeguard product excellence and instill confidence in customers regarding the reliability and consistency of their offerings.

The QA laboratory conducts a wide range of tests, including material analysis, dimensional inspection, performance testing, durability testing, and environmental simulation, among others.

QA laboratory testing ensures that customers receive products of consistent quality, reliability, and performance, leading to increased satisfaction and trust in the brand.

Yes, QA laboratory tests are conducted at various stages of the manufacturing process, from raw material inspection to final product evaluation, to ensure quality and consistency at every step.

Email

info@ptmc.com.pk

Location:

16 km Multan Road, Pakka Mile Stop Shahpur, Lahore, Pakistan