Overview

Advantage

Enhanced Reliability

Thorough components inspection ensures that only parts meeting exact specifications are used in production.

Improved Performance

By identifying & addressing any potential issues during inspection, manufacturers can optimize component performance.

Through the implementation of advanced technologies, process automation, and employee training initiatives, companies strive to elevate their components inspection capabilities to new heights. This commitment to continuous improvement not only ensures the ongoing delivery of top-quality products but also fosters a culture of innovation and excellence throughout the organization, positioning manufacturers as industry leaders in a competitive marketplace.

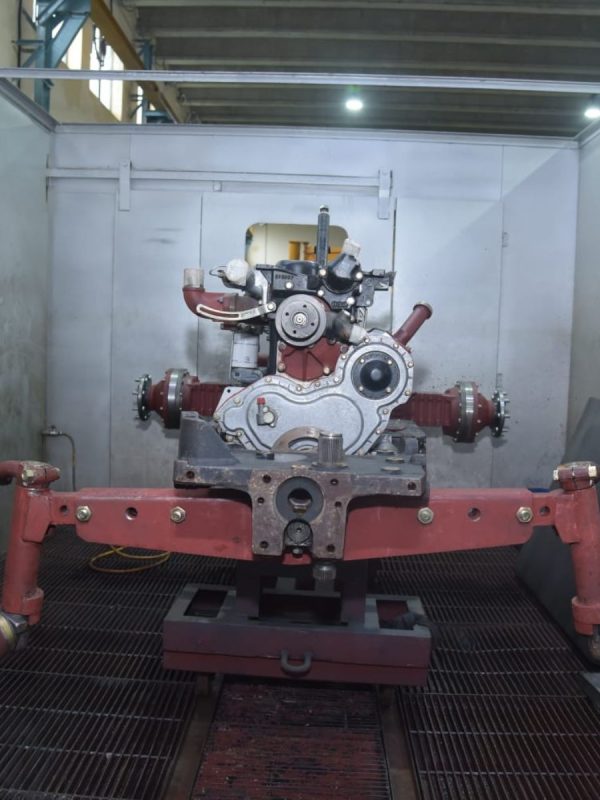

Components inspection is necessary to identify and rectify any defects or inconsistencies in parts before they are assembled into the final product, ensuring quality and reliability.

Components inspection leads to products with higher reliability and performance, ultimately benefiting customers by providing them with durable and efficient machinery.

Various methods such as visual inspection, dimensional measurement, non-destructive testing, and quality control checks are employed during components inspection to ensure thorough assessment and adherence to quality standards.